Weaving Silk Stories - research - Macclesfield Silk Museum & Paradise Mill

- Stephanie Smart

- Jan 23

- 13 min read

Updated: Feb 28

Macclesfield - a town I visited in my twenties when my student boyfriend moved there for a work placement. He was working in IT for the pharmaceutical industry. Which is an interesting link only because AstraZeneca profits today, no doubt with the help of computing, where the manufacture of silk once dominated. That latter industry used the jacquard loom, the history of which is interwoven with the history of the origins of the computer. History is never not intertwined with the present however far we think we have come.

Anyway I have now been back for a second visit. At an early stage of the research for Weaving Silk Stories, my next collection. I went to meet the curators of the town's very own Silk Museum, to start looking at the items in their collection. And also to visit Paradise Mill.

Where it once filled the building Paradise Mill today, as a heritage site, occupies only the top floor. It is next door to the museum and I have to admit that standing between those original looms almost moved me to tears.

Click here for a bit of video about the mill

Honestly I don't think I have ever visited a historic site, that affected me so much. That is, one that seemed imbued so strongly still with the energy of those who went before and now are gone. There is such a strong sense of what was once done and made on site, it seems to fill the air. Guided group visits today involve demonstrations of certain looms. I wasn't on such a tour, there were no machines in operation, but there might as well have been, the atmosphere was rich with the ghostly sound of them. Every one of them, even those in the outer rows which are now falling apart where they stand and being used for parts depending on the available funding, seemed to me to be working. I had a shocking sense of what must have been the absolutely deafening noise. It was cold the day I was there but surely nothing compared to what it must have been working with ones hands for hours on a winter's day in the 1800's. Imagine the chillblains! The floor of Paradise Mill which houses the looms today dates to the 1860's. It is part of Lower Paradise Mill which was constructed next to Upper Paradise Mill (built in 1824) and on the site of an earlier mill building.

I felt indeed like a Southern lightweight artist type as I stood and imagined. One of the curator's own grandmothers was entirely deaf from her work in such a mill and the eye sight loss suffered by silk weaving workers is also documented (I will return to that in another post).

I could also visualise, if not the exact design of a paper garment to be displayed at the centre of this huge space, between the looms themselves, then certainly the idea of a piece standing there. We decided the base of the mannequin it will be on may need to be weighted down so as to stop it falling over from the vibrations that run through the floor when even three or four machines are at work here during demonstrations. When the mill was spread throughout the entire building there were 70 -100 looms working. Today there are 26 Jacquard looms still in their original setting from when they were last used in manufacture. This is believed to be the largest collection of original Jacquard looms in their original setting in the world.

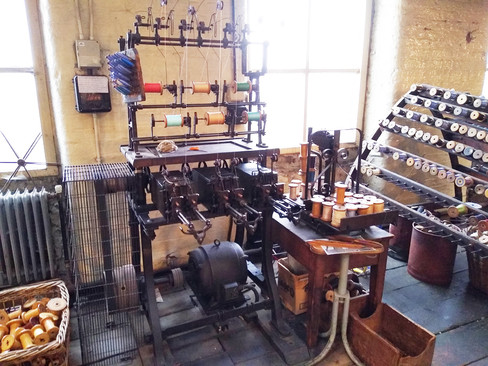

Some of the other machinery that you come across as you enter the space, and towards the back, like the knitting machine and wick winder, were not originally used on this floor but were moved up from lower floors to help tell the wider story of silk production. This is the same with the design room which I walked through on my way out, it would originally have been elsewhere in the building. Likewise the card cutter and the point paper designs but everything is original to the mill itself. To read more do please click through to the Paradise Mill website here

"Macclesfield was once the world's biggest producer of finished silk."

To read more of the history of silk weaving in Cheshire please click: https://en.wikipedia.org/wiki/Silk_industry_of_Cheshire

For a video showing mill workers at the end of the 20th c. please see: https://www.youtube.com/watch?v=gSgf5UTwPFQ

The looms you can see in the photos above are Jacquard looms. The Jacquard mechanism (about which you can read more below) was:

"...invented by Frenchman Joseph Marie Jacquard and first demonstrated in 1801..." It "...simplified the way in which complex textiles such as damask were woven. The mechanism involved the use of thousands of punch cards laced together. Each row of punched holes corresponded to a row of a textile pattern. This modification not only introduced greater efficiency to the weaving process, allowing the weaver to produce, unaided, fabrics with patterns of almost unlimited size and complexity, but also influenced the future development of computing technology."

But it all began with buttons...

Macclesfield thread buttons made in 2022 by Kerry Crofton, part of the House of Embroidered Paper team

Thread button making was being done in the area long before silk weaving. Originally the silk thread would have been wound over and around discs made of wood from Holly trees from Hollins wood in Macclesfield near to Macclesfield. We of course will be using cardboard (and silk thread) to stay true to the ethos of The House of Embroidered Paper, ie. only paper (inc. card), and thread allowed in the making of all of the pieces.

"A domestic button industry had been established in the town by the mid-16th century, although the first mention of silk buttons is not until 1649. In the mid-18th century, when metal buttons became fashionable, the silk-button industry transitioned to silk manufacture in mills"

Button making at first was a cottage industry:

"Macclesfield buttons were initially covered with mohair or linen. Spanish silk buttons were imported into this country in the Tudor times and were the height of fashion. Macclesfield soon began to cover its buttons in silk. There are a series of letters to the Mottershead family in Macclesfield which show that they were involved in making silk buttons in 1649."

Some original Macclesfield buttons are on show in the Macclesfield Silk Museum and held in their stores. It was particularly interesting to see the miniature buttons (my finger is in there for scale) because The House of Embroidered Paper is just beginning to make one third life sized garments which will necessitate tiny detailing. To read more about my research into the history of miniature garments and mannequins please click here

Inside the museum you can read about how it is known that the people of Macclesfield made buttons when Elizabeth I was Queen but that there is no remaining evidence of buttons being made from silk until 1617. Silk buttons seem to have been particularly popular during the 17th century, hence the growth of the industry, Women and children worked at home wrapping the thread around the wooden disk and at this stage the silk used would have been bought to them by pedlars, who would likewise collect the finished buttons and sell them on.

"Many pedlars settled in Flash, a wild area of country between Leek, Macclesfield and Buxton. They were known as the “Flash-men” and some had a reputation for being involved in criminal activities and money counterfeiting. The “Broken Cross Gang” was one notorious group of Macclesfield pedestrian pedlars. They associated with the Flash-men and were known for their thievery. The district magistrates eventually broke up the gang. As the trade became more organised, distribution was handled by merchants in London and Manchester. London was the only legal port for the importing of silk. Merchants from London would bring up silk from the Spitalfields weavers and exchange it for the silk buttons.

- https://www.hollinshomes.co.uk/news/2022/11/3/naming-thistledowns-the-history-of-macclesfield-silk

Different styles of thread button developed as part of similar cottage industries in other parts of the country. Perhaps one of the best known is the Dorset Button, which has at it's heart a metal ring rather than a wooden disk, but which is similarly made from the winding of thread around a base. I will be writing a separate blog post showing photos of some of the thread buttons the House of Embroidered Paper volunteer team are learning to make for use on future paper garments and will include more pictures of the historic examples I saw at Macclesfield Silk Museum.

The buttons on display in the Macclesfield Silk Museum are labelled as being made by Brocklehurst, 1800. So here then I will touch on the work of John Brocklehurst, who held:

"...one of Macclesfield’s two parliamentary seats...from 1832 to 1868."

He was also a banker and his:

"...firm was the largest silk manufacturer not only in the town but in Britain. A public meeting of silk weavers in March 1832 declared that his ‘long and constant endeavours to defend the silk trade’ made him a fitting representative. These efforts continued that July, when Brocklehurst gave evidence to a Commons select committee on the silk trade, urging the need for ‘better and judicious protection’, as Britain’s silk industry had declined since tariffs on foreign silk were reduced in 1826."

I first came upon his name during my research at Macclesfield Silk Museum in relation to his daughter Marianne Brocklehurst (1832–1898) who was an English traveller and collector of Egyptian antiquities some of which I saw on show and in store at the Museum. John's other daughter Emma Brocklehurst was married to John Coucher Dent and lived at Sudeley Castle.

Note: King Henry VIII and his then wife Anne Boleyn visited the castle in 1535;

and it later became the home and final resting place of Henry's sixth wife,

Catherine Parr who remarried after the king's death., she is buried in

the grounds. Elizabeth I also visited Sudelely Castle three times. This

is a nice link to the Royal history I will be featuring in these posts as part

of the research for Weaving Silk Stories.

But before Brocklehurst there was Roe:

"Charles Roe (1715 -1781)...started out in the button trade. In 1743 he built the first silk throwing mill in the town. This mill was based upon Lombe’s mill in Derby, the patent on that technology having just run out. From a humble beginning...Charles Roe later became mayor of the town and developed a copper mining business."

In the mid mid 1820's "...In Spitalfields alone, 17,000 looms were in operation and in Macclesfield hard pressed manufacturers placed the following newspaper advertisement:"

- Whitchurch Silk Mill Past and Present 1988

"The mills were initially powered by water, and later by steam. There were 71 silk mills operating in 1832 employing 10,000 people, but a crash occurred in 1851 and many mill-workers emigrated to the American silk town of Paterson, New Jersey. The silk industry remained active in the town in the 1980s, but no longer dominated. Paradise Mill reopened in 1984 as a working mill museum, demonstrating the art of silk throwing and Jacquard weaving."

"The silk industry remained a large part of the town’s economy well into the 20th century."

And it all sits as the formal end of the very famous Silk Road.

"Everyone knows that the Silk Road begins in China, but how many people know where it ends? According to a recent ruling by the UN World Tourism Organisation, this famous route begins in Xi’an, the ancient capital of China, and ends in the ancient Cheshire town of Macclesfield...Production of silk fabrics began in China in 3,500BC, but did not spread to England until the 18th century. In 1773, London weavers won fixed prices for their work, causing the silk merchants to seek lower prices in provincial centres like Macclesfield, where hand-loom weaving in ‘garret houses’ was gradually replaced by weaving in multi-storey mills..."

Because the silk (raw and finished) had to pass through London to be imported and exported as mentioned above, and because of the industry in Spitalfields, London too sits on this route but in fact it is Macclesfield that was once the biggest producer of finished silk goods in the world.

I will return to the social history details that exist concerning the lives of 20th century mill workers and others linked to the mill that the Silk Museum hold records of. But first, I want to ask you to pause to gaze at, if only in images, the Paradise Mill looms themselves; their construction, their lines, their symmetry, the threads, hanging row after row... It may be just me but I find them quite mesmerizing, and certainly inspiring. Immediately I was seeing wide skirts and long dresses with echoes of these lines in their designs.

You can click here to watch a video about replacing and tensioning the warp threads.

I've taken this image still from the end of the video, of the knots created, because I plan to incorporate them into a design.

Though I was as struck simply by the aesthetics of the looms at Whitchurch Silk Museum (to see images of those please click here) there is of course a difference. These ones have reems of hole punched cards hanging above them.

"The Jacquard machine...is a device fitted to a loom that simplifies the process of manufacturing textiles with such complex patterns as brocade, damask and matelassé. The resulting ensemble of the loom and Jacquard machine is then called a Jacquard loom. The machine was patented by Joseph Marie Jacquard in 1804, based on earlier inventions by the Frenchmen Basile Bouchon (1725), Jean Baptiste Falcon (1728), and Jacques Vaucanson (1740). The machine was controlled by a "chain of cards"; a number of punched cards laced together into a continuous sequence. Multiple rows of holes were punched on each card, with one complete card corresponding to one row of the design...This mechanism is probably one of the most important weaving innovations as Jacquard shedding made possible the automatic production of unlimited varieties of complex pattern weaving. The term "Jacquard" is not specific or limited to any particular loom, but rather refers to the added control mechanism that automates the patterning...This use of replaceable punched cards to control a sequence of operations is considered an important step in the history of computing hardware, having inspired Charles Babbage's Analytical Engine."

Joseph-Marie Jacquard (1752-1854) A woven silk La Memoire Portrait

Click here to see the original on sale at Bonhams

Executed in 1839 on the programmable Jacquard loom by Didter Petit et cie, Lyon

The cards in and of themselves are intriguing and attractive. I found the way they are stitched together interesting and I was taken aback at the simplicity of the tools used in their production (a hole punch). Working out where the holes should be is rather more complex.

The House of Embroidered Paper volunteer team and I have begun experimenting with weaving using a combination of paper and thread on a loom made from a piece of cardboard.

And we've been trying card weaving, to make ribbon, using simple squares of recycled cardboard that is likewise simply hole punched, in the corners.

I've learnt during research at Whitchurch Silk Mill that as part of the design process weavers decide on the colours and patterns of striped weaving designs by experimenting with sketches and testing these on card wraps - small pieces of card wound with threads to mimic the final design, which allow the weaver to try out various options. It's amazing what can be produced by combining cardboard and weaving.

Of course the designs that are possible on a Jacquard loom are much more complex than my early experiments. The silk designs below were on the looms in Paradise Mill when I visited. The marron and black piece that you can see in the first image is an unfinished piece that remains on a loom from when the mill ceased to manufacture. There were various pieces begun and abandoned on the day the mill closed.

The red, yellow, green, blue and black design can be seen being made today on the demonstration loom. This original design was created by Leslie Winnell whose father you will be able to read about in a future post.

Leslie Winnell:

"Leslie Winnell, was born 23rd September 1919, he had a younger brother named Maurice, born 1924. In the early 1930s, Leslie attended Macclesfield Central School and we have exercise books, school reports and magazines from his time there. He also attended the Macclesfield School of Art while Ferdinand M. Bonnaud was principal. Bonnaud wrote Leslie a letter of recommendation on 20th September 1935. Leslie completed textile examinations and won prizes while at the school.

He began working for James Arnold & Co. Ltd. in 1933 when he would have been 14 years old. In 1935 he became an apprentice at Arnold’s to learn textile design for five years and then for a further two years as an improver. An improver, in this instance, was a person who had completed an apprenticeship but was not seen as fully qualified, perhaps due to age or lack of experience. World War 2 began in 1939 while Leslie was still an apprentice at Arnold’s and during this time he was a member of the firm’s Fire Squad. The Fire Squad would guard the mill overnight and hurry to protect the mill if there was an air raid warning. Perhaps because the role required people to lurk around the mill in the dark, Leslie was given a card which listed his name, address and national registration number before stating that Leslie: ‘is a member of the firm’s Fire Squad and is authorized to be on the premises at Wood St. Mill between the hours of (9 P.M and 1.30 A.M and to proceed to the premises at any hour in the event of an Air Raid Warning.’ On 16th March 1943 Leslie received a cash bonus along with a letter of appreciation for his loyal conduct from the Charles B. Arnold, Chairman of the Board of Directors of James Arnold & Co. Ltd.

In the collection we have lots of designs, ties and textile samples designed by Leslie including a sample of Macclesfield Stripe.

Leslie continued to work as a designer for James Arnold & Co. Ltd. at Wood Street Mill until the 1970s. During that time, he worked not only with silk but also with the artificial silks that were gradually replacing it in the Macclesfield textile industry. In his time at James Arnold he also worked with polyester and terylene, the synthetic fibre created at ICI.

By the time Leslie Winnell died in 1988 at the age of 68 the silk industry was dying in Macclesfield, being replaced with the pharmaceutical industry. At the start of the decade, the Silk Museum had been set up to preserve the history of the town and its fast vanishing industry. After Leslie’s death, his brother Maurice donated many items connected to Leslie to the museum. He also conducted extensive research into the Winnell family tree on which much of the above was based."

© Macclesfield Silk Museum

The Jacquard cards below show how he worked.

As I mentioned earlier Paradise Mill is set up today with the design office layout placed behind the looms. It would originally have been on one of the lower floors from where other businesses now operate, but it remains as evocative.

You can also see where the loom card punching was done by hand:

Click here to hear from Cliff Brown a textile designer

And in the museum you can see how it began to be mechanised.

I loved this beautiful work bench.

And in the final rooms at Paradise Mill you feel as if you should clock out - more hole punching!

Next door there are many more machines that would have been involved in the manufacture of silk garments.

For spinning, winding braid, tassel making etc

And you can see ribbon weaving on an industrial scale:

I am writing other posts about the pieces I saw in store at Macclesfield Silk Museum and there is much more to come about the research for Weaving Silk Stories the collection.

Weaving Silk Stories is a new project in partnership with the independent charity Historic Royal Palaces, which is due to launch in 2027.

Paper sponsorship by Duni Global